产品概述

GDH系列堆下活化给料机适用于各种露天堆场、条形储料场、穹顶仓储料场等各种散料堆场的对外输送,给料机的凸起圆盘可将激振力传递给整个料堆,使卸料变得更加容易,这样堆场的料堆就能随之振动起来并从给料机圆盘中落下。GDH系列堆下活化给料机系统主要由活化给料机、低净空流量控制闸门、液压系统、PLC控制系统、安全装置等组成。其中活化给料机的振动功能用于加大煤流,有效解决静态落料时鼠洞和架桥的问题,低净空流量控制闸门用于控制煤流,液压系统为各种机械设备提供动力,控制系统用于物料输出过程中所有设备的检测和自动控制。

产品特点

●与传统给料机相比可降低输煤沟高度4-5米,节省土建施工成本50%左右

●给料机的活化性能可增大物料卸料角度,减少地面辅助机械作业量

●间歇性振动,节省电力能源,延长驱动部件使用寿命

●动力装置采用数字液压系统驱动,系统运行稳定可靠

●采用低净空流量控制闸门,可实现物料流量精确给料控制

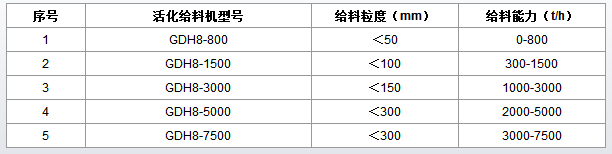

产品规格型号系列表

Founded in 1994,Shandong Borun Process Industrial Technology Corp., Ltd. is located in High & New Technology District of Zibo city, Shandong, China.

As a high-tech enterprise at national level, inspection-free enterprise, contract-honoring and promise-keeping enterprise at provincial level, Borun has passed ISO9001 Quality Management System Certification and ISO 14000 Environmental Management Systems and awarded the right to deal with international trade. Now we are the membership unit of China Coal Industrial Association Coal Separation Branch, China General Machinery Industry Association Separation Machinery Branch, Chinese Mechanical Engineering Society Engineering Ceramics Specialty Committee, China Industry Anticorrosion Technology Association, and executive director of China Association of Coal Processing & Utilization, etc.

Borun mainly focus on the production, R&D and marketing of four series products like wear protection products, coal washing equipment, material handling systems and chemicals. Our products have excellent performance and perfect after-sales service.

Wear protection series mainly include wear-resistant materials, wear-resistant products and wear-resistant parts. As a professional manufacturer and supplier of wear protection products, we offer all-directional solutions from application advice, on-site measurements, design service, manufacture to the proper installation. And, according to different conditions, we can do the combined application by selecting the most appropriate wear-resistant materials to provide optimal solutions to reduce the production cost.

Coal washing equipment mainly includes series of centrifuges and automatic preparation & dosing systems. Centrifuges series cover Horizontal Screen Bowl Centrifuges, Horizontal Vibratory Screen Centrifuges and Horizontal Scroll Screen Centrifuges. Automatic preparation & dosing systems include Automatic Flocculant Preparation & Dosing Systems, Automatic Coagulant Preparation & Dosing Systems, Automatic Flotation Agent Preparation & Dosing Systems and Automatic Coal Slurry Monitoring Systems.

Material handling series mainly include rapid precision & intelligence loading systems and activated feeding systems. Rapid precision & intelligence loading systems include precision train loading system, precision truck loading system, precision train&truck loading system and precision loading system under silo; activated feeding systems include stockpile activated feeder and bin activator. Material handling system involves the whole process of coal discharge, coal storage, coal conveying, coal weighing and coal loading. Rapid precision & intelligent loading systems can realize multiple-batch loading for single wagon with features like high loading speed and accuracy. Borun can offer complete solutions for the customers.

Borun has more than one hundred sets of equipment like machine tools, measuring instruments, dynamic balancing machines and welding robots. Backed up by almost one hundred professional technicians and skilled service people, Borun can provide technical services such as consultation and proposal design for free. It will also give the end-users the detailed product catalogues, drawings, technical data, operational manuals and all the other necessary information to enable that they know well about how to use and maintain the products. Besides them Borun will provide lifetime services and quality tracking services for the products it offered, and pay return visits regularly to the customers.

Our company has made and will continue to make constant efforts to promote the advancement of this industry and spare no effort to strive for perfection by focusing on every detail, so that we can provide better products and services to meet our customers' increasing demands.