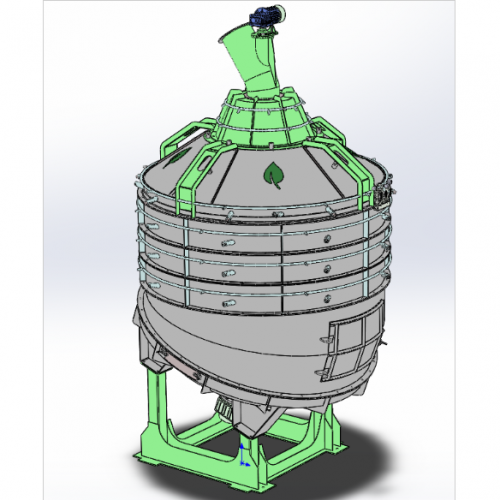

连续造粒机是一种适用于各种粉料的造粒,增湿设备,可靠性强,稳定性高。

Continuous Granulator is a humidifying 、high reliability and high stability equipment, which is suitable to all kinds of powders .

1 产量大。该设备采用了高速布料,变频调速等高新技术,实现连续造粒,大大提高了产量;

1.Large production. Adopting high speed distributing devices and frequency control to improve production and continuous granulating.

2寿命长。连续造粒机底盘内衬耐磨防粘衬板,有效防止含水物料粘壁、板结,大大提高了设备的使用寿命;

2. Long life. Chassis lined with wear-resisting anti-adhesion lining board,it can prevent wet materials sticking board and harden, so thus improve the working life of equipments.

3自动化控制。采用远程集中控制和全自动化操作,通过编程,设置工艺参数实现自动造粒等先进可选功能;

3. Auto-control. We can realize remote centralized control and automation operation via programming & setting technology parameters.

4 维护简单。连续造粒机上壳体设有检修门,打开检修门可以调节间隙、更换易损件。

4. Easy maintenance. Continuous granulator’s shell is equipped with access door for adjusting clearance and changing vulnerable parts.

连续造粒机通过高速旋转的布料器均匀布料,在旋转的叶片组带动下,水雾与细粉物料充分接触,实现物料多维度翻滚的反复运动,形成颗粒。

The method of even distribution by high-speed rotating of distributing devices , spray has a complete contact with fine powder materials under the driving rotating blades, so as to realize the material repetitive movement of the multidimensional roll .

主要适用于陶瓷、瓦业、耐火材料、医药、化工、食品、化肥等需要原料成粒行业。

Ceramics、tiles、refractory materials、medicine、chemical、foodstuff、 fertilizer as so on.

类型 Model | 入料粒度 Feed size(mesh) | 出料粒度 Discharge size(mesh) | 入料含水率 Moisture of feeding(%) | 出料含水率 Moisture of discharging(%) | 产能 Production capacity(t/h) | 设备功率 Motor power (Kw) | 重量 weights (t) |

| >200 | 20-120 | ≤2% | ≤13% | 0-5 | 7.5 | 2 |

EG2400 | >200 | 20-120 | ≤2% | ≤13% | 5-15 | 11 | 2.5 |

| >200 | 20-120 | ≤2% | ≤13% | 15-25 | 18.5 | 3 |