高效好氧生物废水处理技术--HCR工艺及工程实例

技术说明

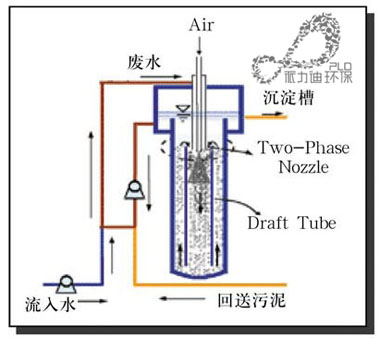

我公司引进的HCR工艺是德国克劳斯塔尔(Clausthal)工科大学物相传递研究所发明的新废水处理工艺。它融合了当今的高速射流曝气、物相强化传递、紊流剪切等技术,并具有深井曝气和流化污泥床的特点,它的使用是好氧生物处理技术的一个飞跃。HCR系统主要包括:集成反应器、两相喷头、沉淀池(或气浮池)以及配套的管路和水泵等(见下图)。

工艺特点

应用实例

目前已应用HCR(High Performance Compact Reactor)工艺处理的废水类型有:奶品加工废水、酵母生产工艺废水、造纸厂废水、化工废水、印刷业废水、屠宰废水、填埋场渗滤液及城市污水等。其中化工和食品废水的处理工程较多,已分别在我国多个企业建成投入运行。

图为无锡制药厂污水处理系统一角

Pailidi Environmental Engineering Co., Ltd. was founded in March 2008, is the research and transformation base of the Institute of Environmental Science, Fudan University, and with the Institute of High Energy Physics of the Chinese Academy of Sciences, Tsinghua University, Zhejiang University of Technology, Shandong University, Harbin University of Technology and other domestic scientific research institutions, specializing in industrial organic waste gas treatment of environmental protection new technology research, supporting equipment processing and atmosphere, sewage and other environmental engineering general contracting comprehensive high-tech enterprises.

At the same time, Palidis set up environmental protection academician workstation, Shandong plasma waste gas treatment research and development center, environmental protection enterprise of environmental engineering R & D center, there are a large number of innovative, practical technology born here. The company has registered capital of 50 million yuan, has environmental engineering design class B qualification (waste water, waste gas), environmental protection facilities operation and construction project contracting qualification and many other qualifications and perfect certification system.

As a technical enterprise in the industry of industrial odor gas management, perindi has always devoted a great deal of human, material and huge amount of capital to the atmosphere governance, sewage treatment and other environmental technologies with a high sense of social responsibility. At the beginning of the establishment of the company, the DDBD dual medium resistance of the DDBD was introduced for more than 10 years. When introduced, the technology was introduced in the completion stage of the laboratory principle prototype. After 8 years of engineering experiments and research of more than 400 different exhaust sources, the industrial application of DDBD has been realized. A lot of experience has been accumulated and a "low temperature plasma technology" has been created in the world. Palidis is known as the "low temperature plasma technology" industrial waste gas management brand. The technology is energy-saving, environmental protection, and has a wide range of applications. It has been rated as the national Torch Program, national environmental protection demonstration project, the first batch of key recommendation technologies of environmental protection in Shandong Province, and the national environmental protection technology project of National Encouragement and Development. The industrial application of the advanced technology and equipment is the first batch. The industrial application of this technology provides an effective way and technical basis for the odor purification, subverts the traditional technology. At the same time, combined with other waste gas treatment technology, more than 20 new technologies are developed, 60 items are applied for special profit, and the waste gas treatment project is completed by the end of 2015, and 40 works to complete the waste gas treatment project. The 408 item, production standard industrial waste gas treatment equipment 16 series, 150 varieties. In recent years, the company has developed a three-phase multi-medium catalytic oxidation technology, high performance liquid phase TRS purification system, mixed solvent dry cloud recovery and reuse technology, efficient water film separator, ultra clean emission and energy saving practical technology, greatly improved the company's market competitiveness. It has become a modern high-tech enterprise with R & D and design, project consultation, production and sales, and engineering general contracting.

In addition, the Palidis team has more than 10 years of experience in industrial sewage treatment. In the pharmaceutical, coking, printing, dyeing, landfill leachate treatment and other industries, the industrial wastewater treatment and municipal sewage treatment industry, has done a large number of high-quality projects. Has been the environmental protection management department and the user's consistent praise.